Ingalls Field Airport is the highest airport east of the Mississippi River, situated at nearly 3,800 feet elevation. It features a 5,600 by 100 feet runway with an ILS approach for runway 25, accommodating various general aviation aircraft, including medium turboprops and light to medium jets. Visitors to Ingalls Field Airport enjoy stunning landscape views that enhance the flying experience. Its elevated location offers crisp mountain air and expansive vistas, making it appealing for both pilots and passengers. The airport is a testament to engineering and the spirit of flight, providing a serene setting and efficient facilities for a memorable journey, whether for business or leisure.

Athens Building Corporation is set to construct a Terminal Building to assist travelers arriving in and departing from Hot Springs and the surrounding area. This new Terminal Building will be a state-of-the-art facility designed to enhance the travel experience for passengers, featuring modern amenities and efficient services. The structure will include spacious waiting areas, advanced check-in counters, and comfortable lounges to ensure a seamless and pleasant journey. Additionally, the terminal will be equipped with eco-friendly technologies to minimize environmental impact, aligning with Athens Building Corporation’s commitment to sustainable development. As always, Athens Building Corporation is dedicated to delivering a project that reflects quality craftsmanship and innovation, setting a new standard for regional travel infrastructure.

April 2025

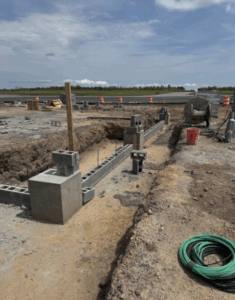

Work at the job site began with digging the footers, followed by installing rebar mats and pouring concrete. The team meticulously ensured that each step followed the architectural plans, guaranteeing the stability and longevity of the structure. Once the concrete is cured, the crew will move on to erecting the steel framework, which will form the skeleton of the new building.

In April, work focused on footer excavation, rebar installation, pier forming, and concrete placement for the new terminal building, with frequent inspections by Schnabel Engineering to verify footing subgrades, reinforcing steel, and concrete quality. Our crews from Extreme Design handled excavation, tying rebar, and pouring piers, while Athens provided site cleanup and support. Multiple pours were completed with Alleghany Ready Mix supplying various volumes of 4,000 psi concrete, and engineers documented compliance with design loads and reinforcement requirements along multiple column lines. Challenges included layout adjustments, equipment fixes, and benchmark discrepancies requiring Racey Engineering to reset accurate control points. By the end of the month, numerous footers and piers had been poured, reinforcing steel inspected, and site preparation advanced despite weather changes and coordination issues.

May 2025

June 2025

The exterior CMU walls and footer were prepared and cleaned in order to apply waterproofing. This waterproofing solution was carefully selected to ensure maximum protection against moisture infiltration, a crucial step in maintaining the integrity of the structure. Once the waterproofing process was completed, the team moved on to install insulation panels, enhancing the building’s energy efficiency and contributing to a more sustainable design. The attention to these details underscored the commitment to quality and resilience in the construction of Ingalls Falls Airport.

Applied adhesive/2″ R-10 Foam Board and 6″ seam tape. Additional 2″ R-10 Foam Board arrived.

Grout was applied to the concrete masonry unit (CMU) cells, commencing at the northern front and advancing along the western edge. Ready Mix delivered and dispensed five yards of grout.