Athens Building Corp. is awarded the contract for Historical Preservations to the New Point Comfort Lighthouse. The Scope of work provides for the complete restoration of the existing Lighthouse including the installation of scaffolding, sandstone repairs, masonry repairs, replacements of windows and doors, repairs to gallery catwalk, repairs to lantern room, foundation repairs, waterproofing, installation of solar panels and other electrical work, remediation of asbestos and lead, installation of site signage. New Point Comfort Light is a lighthouse in the Virginia portion of the Chesapeake Bay, United States, off the tip of the Middle Peninsula. Finished in 1804, it is the third-oldest surviving light in the bay, and the tenth-oldest in the United States. President Thomas Jefferson appointed Elzy Burroughs as the first Keeper and New Point Comfort Lighthouse was first lit on January 17, 1805. Since then its history has reflected that of the United States. The British Navy occupied it for several weeks during the War of 1812 before leaving it in shambles and burning the keeper’s house.

Attached, you can view the original 1804 Request for Proposal for the Construction of the Lighthouse. The aforesaid buildings to be erected on such site as shall be designated by the Secretary of the Treasury or other person authorized on behalf of the United States. Dated at the City of Washington the fifth day of March 1804. (Signed) Elzy Burroughs

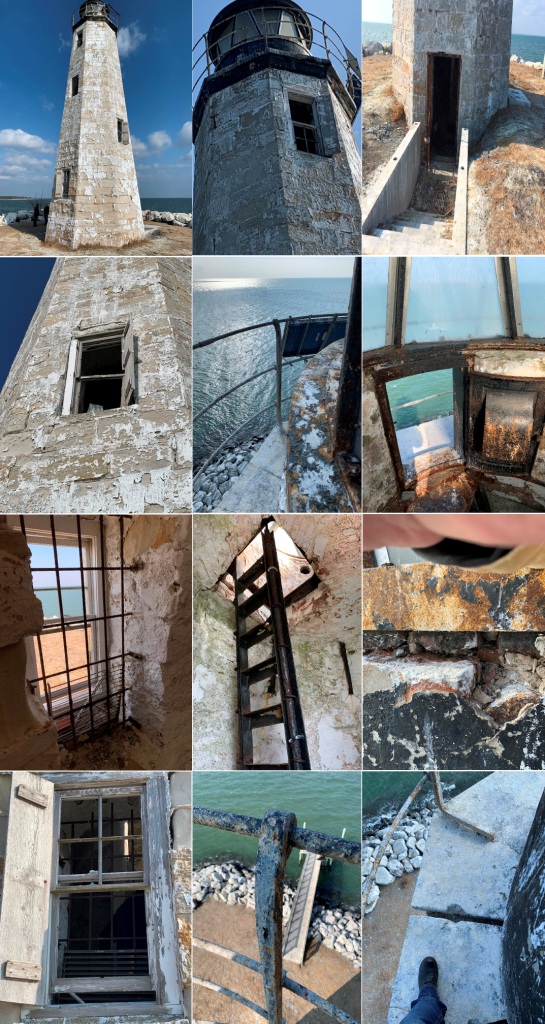

Existing Conditions as of February 2020

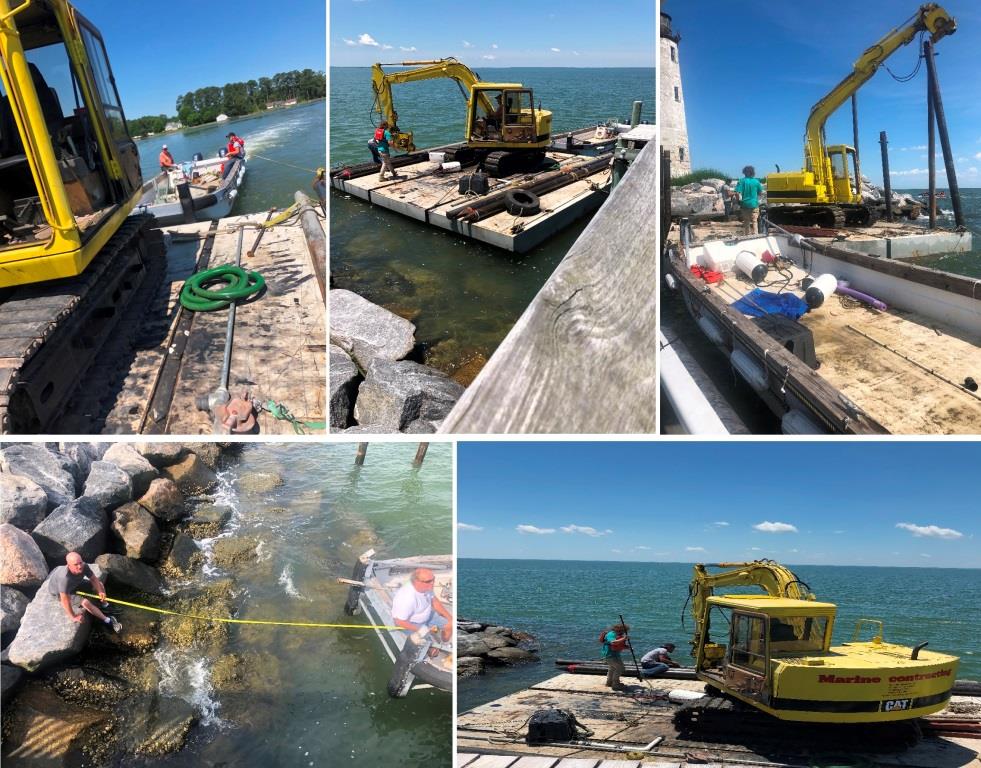

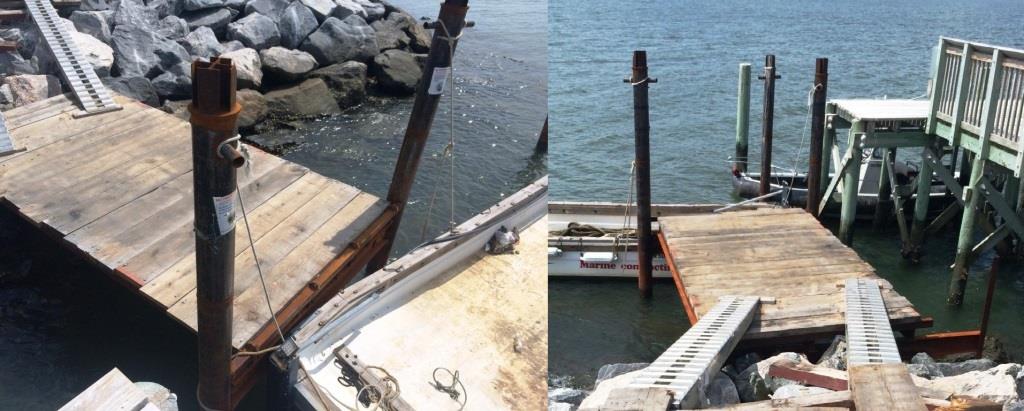

6/15/2020 – Mobilization Begins

August 15 2020 – Overcoming the Milestone Challenges

When Tom White, Senior Estimator brought this project to the table for consideration for proposal, he indicated that it posed three difficulty milestones. The first was getting equipment, supplies and people to the Island. The second was the erection of a scaffolding system needed in order to be able to perform the work required by the project documents. The Third and greatest obstacle was the ability to bring the 16K Pound Top down to the ground in order to restore it. Through much collaboration of the estimating team, many ideas were tossed as to how to overcome these milestones. Collaboration rendered solutions such as large barges and elaborate cranes, helicopter crane, and even use of snorkel lifts. Two weeks prior to the bid date, management expressed to Tom that this project was one that Athens Building wanted to be a part of. Tom went back to the drawing board and developed a work plan that “just made since”. His vision and selling point to management was simple. “We need to reconstruct this structure the same fashion that it was built by.” At the time of Thomas Jefferson, there were no Helicopters, Large Barges with Cranes or Snorkel Lifts he stated. They simply used scaffolding with pullies and erected the structure as it stands today. Utilizing today’s technology, the First Milestone was decided to be conquered using a series of Metal Spuds aligned in a way to support a landing which in turn will support a bridge to load Equipment, Supplies and Workers onto the island. Milestone number one is achieved and we are ready to proceed with Milestone Two. Our success on this project is largely contributed to our team and partners. None of this would be possible without the dedication of Mr. Gary Bunch with Marine Contracting. Mr. Bunch is vital to the maritime operations and a most valuable member of our team. In addition to Mr. Bunch, this project would not have been viable to bid without the early on assistance of Wayne and Jeanie Hudgins of Horn Harbor Marina.

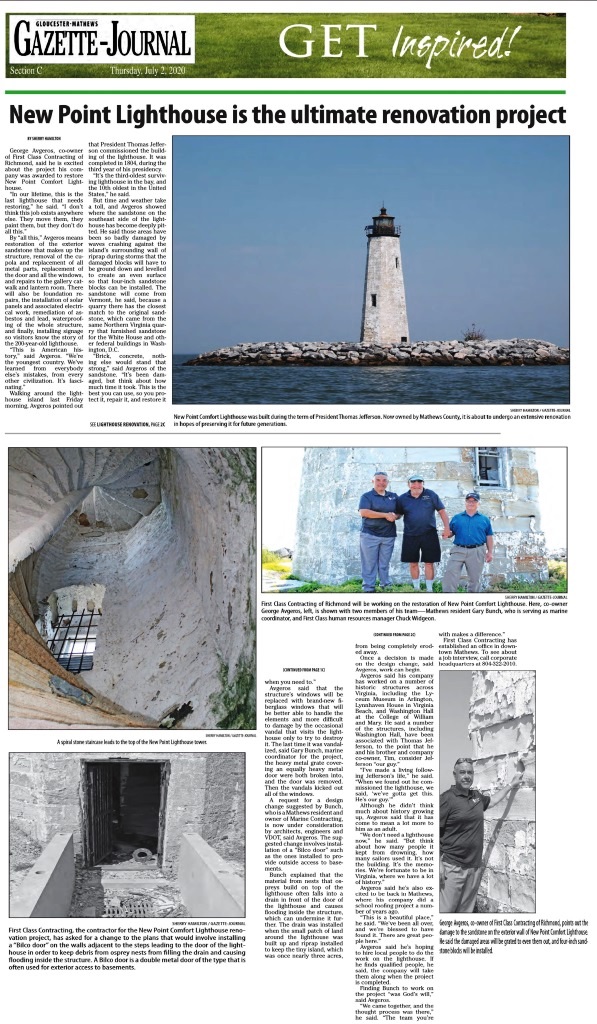

July 2 2020 – Community is excited about the Project

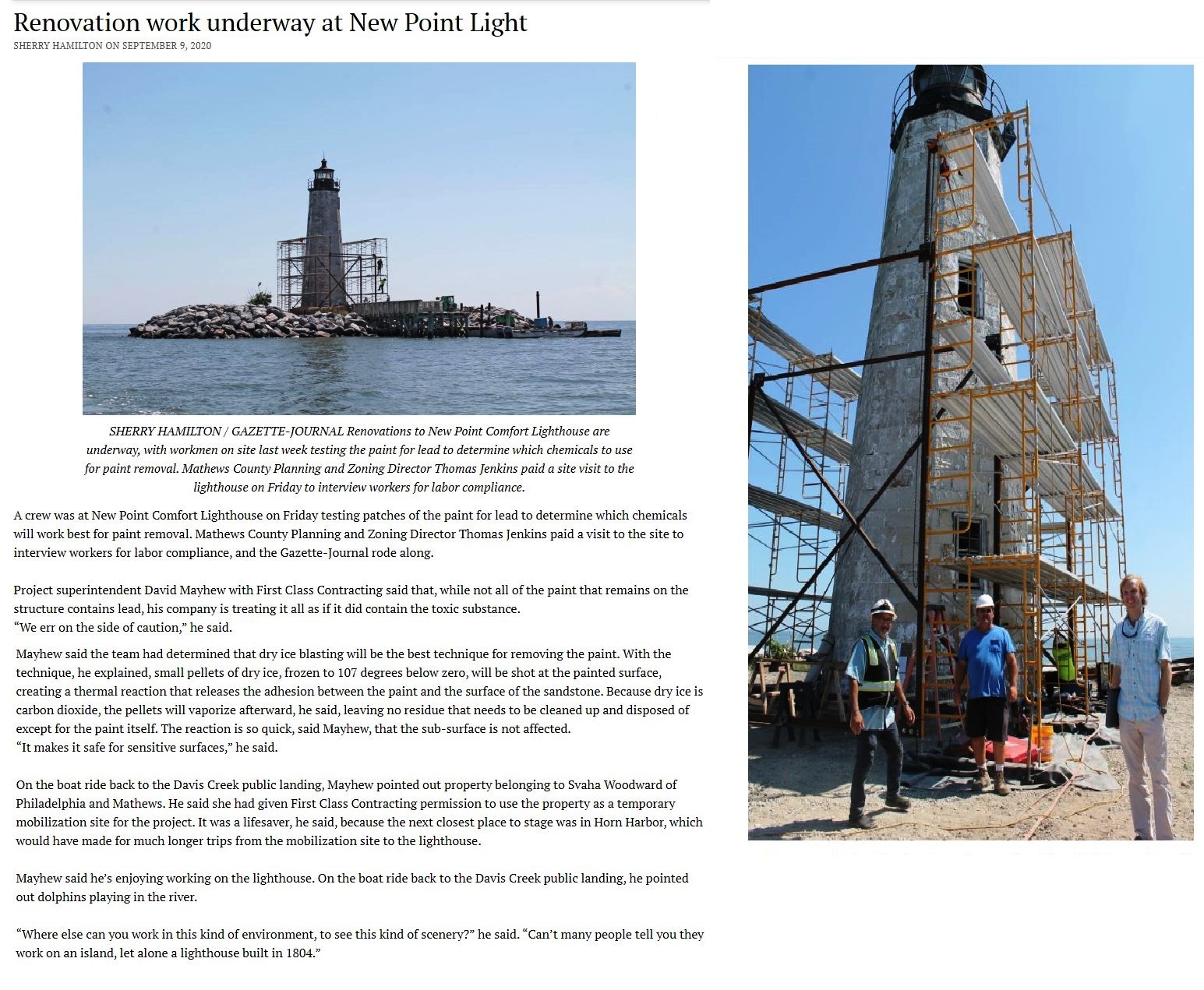

September 2020 In the News

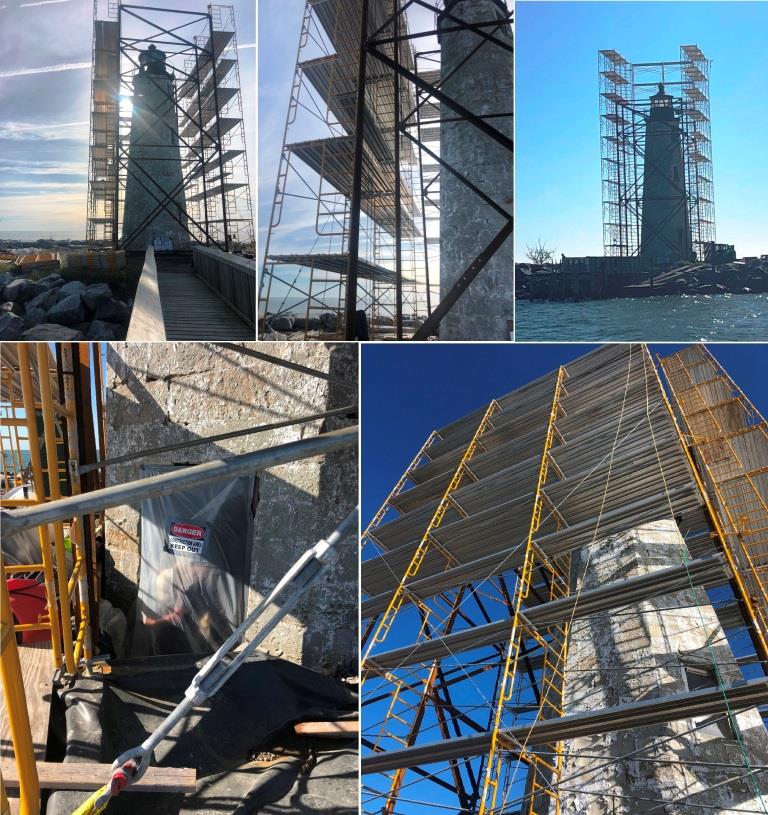

October 12 2020 – Milestone Two is Accomplished despite challenges from Hurricane Season

October 12 2020 – Milestone Two is Accomplished despite challenges from Hurricane Season

Milestone Challenge Two was so far the most challenging task. Hurricane Season has not allowed for many working days 85 feet above sea level. Fortunately, with Tom White’s vision and Tom Zannino’s design, the Superstructure has sustained 62MPH winds thus far without any damages. When Athens set out to get a scaffolding plan designed for the project, there was only one name that came to mind. Zannino Engineering Group headed by Tom Zannino not only has the experience and reputation to design such a structure, but also the innovation in design techniques in order to make it possible to build on such a small site footprint. Zannino has been a Partner with Athens Building Corp. for many difficult projects in the past. The design solutions they provide to us are always unimpeachable and as far as this project, they knocked it out of the park. Special Thanks to Michael Mitchel and John Ruger at West End Machine for the time vested in shop drawings for the Scaffolding Structure. Additionally, we would like to thank Mrs. Svaha Woodward for her gracious contribution to our efforts. Mrs. Woodward is one of the most generous and Bay friendly individuals we have encountered and we will be forever grateful for all she has provided to us.

November 28, 2020 – After 200 years, the Lighthouse is Topless

Milestone Three is now conquered! The Lighthouse Top is on the ground, dismantled and ready for restoration. Lowered 68 feet ever so gently to the ground, the operation went as planned. This third and most complex milestone could not have been accomplished if not for the Knowledge, Honed Skillset, and Can-Do attitude of our Project Superintendent, David Mayhew. Along with our #2 on the site Jacob Mayhew and the Sams’ Richardson’s, Tom White’s vision of construction methodology is accomplished. Several others that we need to acknowledge here that have helped us in our venture are, M&M Building Supply. They have been most accommodating in making sure all of the materials we need are on the shelf. Great Vendor Partner. The Marina at Davis Creek. Craig has been more that accommodating in making sure our boats are running and full of fuel. Last but not least, Conrad Bareford who has been a saint in letting us stage on his property in town.

Milestone Three is now conquered! The Lighthouse Top is on the ground, dismantled and ready for restoration. Lowered 68 feet ever so gently to the ground, the operation went as planned. This third and most complex milestone could not have been accomplished if not for the Knowledge, Honed Skillset, and Can-Do attitude of our Project Superintendent, David Mayhew. Along with our #2 on the site Jacob Mayhew and the Sams’ Richardson’s, Tom White’s vision of construction methodology is accomplished. Several others that we need to acknowledge here that have helped us in our venture are, M&M Building Supply. They have been most accommodating in making sure all of the materials we need are on the shelf. Great Vendor Partner. The Marina at Davis Creek. Craig has been more that accommodating in making sure our boats are running and full of fuel. Last but not least, Conrad Bareford who has been a saint in letting us stage on his property in town.

In addition to the completion of the Third Milestone, the team has progressed with the paint and lead removal from the interior of the structure as well as 30% of the exterior surfaces. Grinding out of all of the interior joints as well as demolition and dismantling of the brick walls.

In addition to the completion of the Third Milestone, the team has progressed with the paint and lead removal from the interior of the structure as well as 30% of the exterior surfaces. Grinding out of all of the interior joints as well as demolition and dismantling of the brick walls.

March 4, 2021

Although the winter has been a bit brutal in the bay, work on site has progressed slowly. More importantly, the show must go on. Our vendor partners have been working non stop behind the scenes in order to meticulously prepare all of the materials needed to complete the Project. West End Machine of Richmond, VA has been hard at work restoring the precious metals.

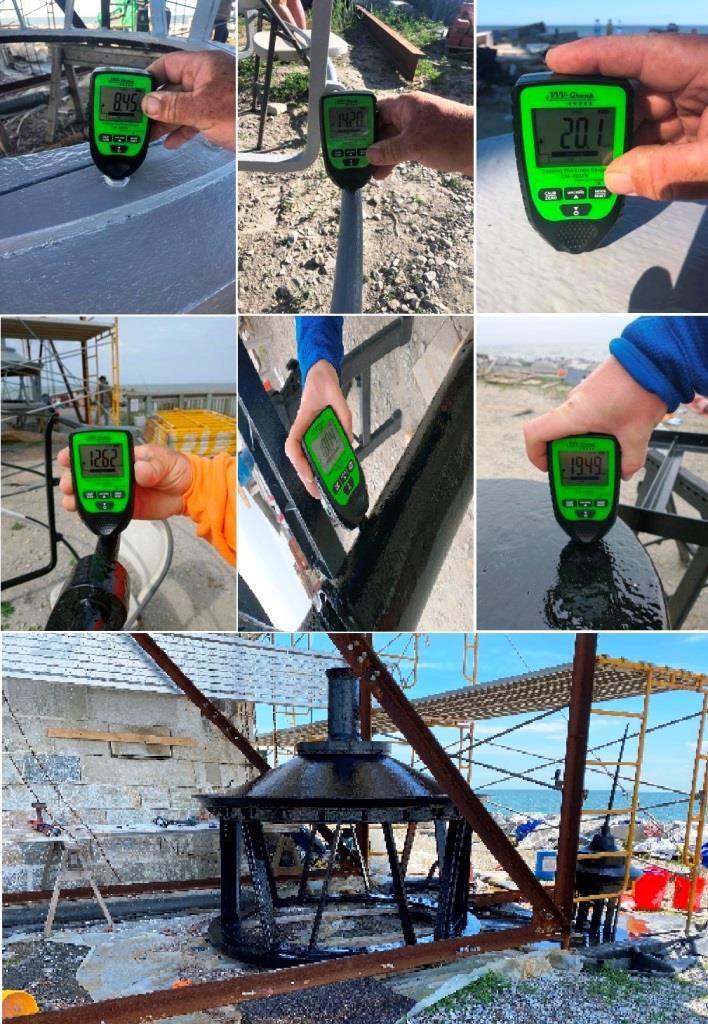

Envirocon has been working hard in order to remove all of the lead based coatings from the surfaces.

Attached is video of the Ice Blasting method used. ICE BLASTING Our Historic Masonry crews have been working when the weather is cooperating in order to get the lifts in place.

Our Quality Control manager has brushed up on the stone restoration process at the Cathedral Stone training facility, in preparation for the next phase in the process.

Meanwhile, Heath Blackburn of Black River Quarries in Vermont has finished mining, processing and is almost ready to ship the Mica Schist stone pavers.

Below is the video of how the 12 foot saw cuts through the mined stone block. This process runs day and night until the slabs are cut to a thickness of 4 inches, prior to being cut to the profile required to create the pattern. Stone Cutting Video

We are pleased with the quality of work we are achieving. Architectural Windows has shipped the windows and they are in our staging area. River City Industrial has completed the new Metal Fabrications, and Phoenix Doors of Ohio has started on the fabrication of the Historic FRP Door.

May 2021

The Progress continues as we are able to find some breaks in the weather. Along with a Dynamic A/E Team, our vendor partners are with us every step of the way to ensure the Project performance meets the demanding conditions of the site. After all, it was never designed to be standing tall in the middle of the Chesapeake Bay.

Mica Schist Pavers. Found their way from Vermont to the Chesapeake Bay. Shipped on a truck, barged to the island, picked up by a forklift, lifted to the top by chain falls, installed by Experts.

Stone Restoration. John Biehl from Cathedral Stone visited for two days and fine tuned our crew on procedures for Historic Stone Treatment. John reviewed and worked along our team the proper process for stone cutting as well as stone chipping. Cathedral Stone Products is not only the leading manufacturer of Historical Masonry products but a valued team member on our project. Upon completion of John’s visit, Athens Building Corp. committed four of our journeymen to attend a certification workshop at their facility in Maryland. Along with the journeymen, Cathedral Stone certified our Quality Manager, Ulysses Avgeros as a certified Historic Masonry instructor.

Our Work, Stone Patching the Correct way. Athens Building Corp. has the largest certified Historic Masonry crew in Virginia!

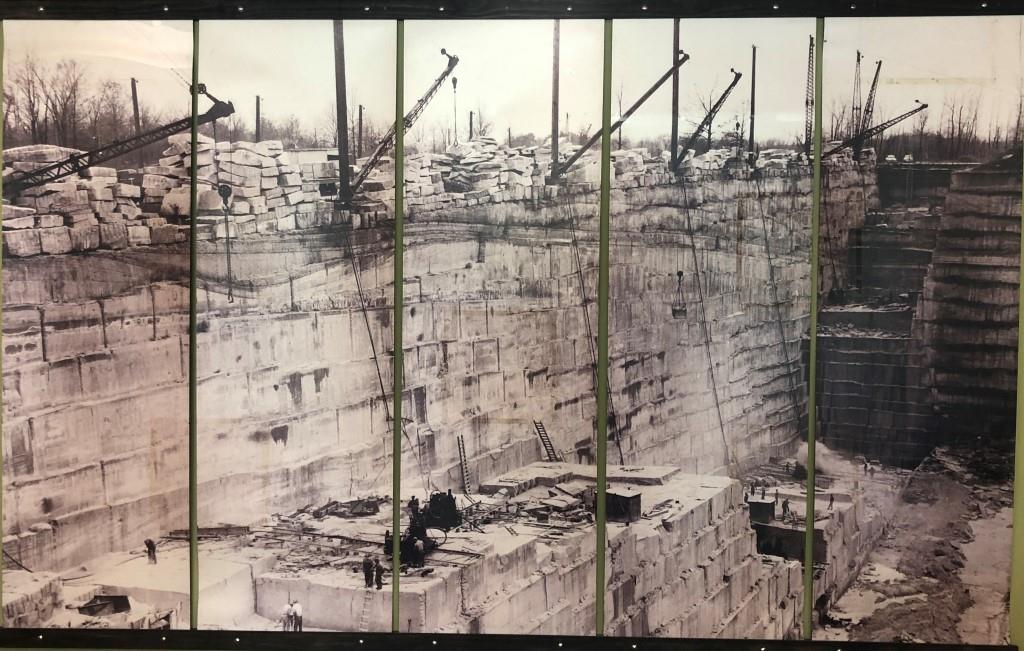

Stone Dutchman Repairs. All the Sandstones were hand picked and picked up from Cleveland Quarries in Ohio.

Masonry – Brick, non Historic Structural Wall

Industrial Coatings.

PPG has provided to be an invaluable partner in the project for us. They have provided not only state of the art materials in order to accommodate the Project requirements, but the technical support and oversight needed to get the job done right! Virtual meetings with their top tier technical support staff as well as quality control monitoring assistance, we are proud to have PPG as a long standing partner on our Projects.

The pictures below demonstrate the passion PPG has emphasized for our efforts. They assisted us from the onset of the surface preparations, all the way to the finish system.

June 2021 Re-Assembly and Final Finishing

The Re-Assembly Process has commenced, the Top Rails are installed, Windows are on the Island and are being prepped for install. Top is set for installation depending on the wind and weather. The crew is preparing for the Architectural Coatings on the Exterior stones.

Lighthouse Top is hoisted and Installed back in place.

Exterior Surfaces are gently cleaned in order for the Silicone Phosphate coating to properly adhere.

July 2021 – Final Phase

Parging is complete.

Stone Architectural Coatings. This is not a paint. Cathedral Stone’s Potassium Silicate Coating forms a molecular bond with the masonry substrate – it will not peel. The incredible 92 perm rating helps, but the big difference between potassium silicate paints and latex or acrylic paints is the bonding characteristics. This is incredible Stuff. It will ensure years of service even at these extreme conditions.

The Structural Steel used for the lifting operations is dismantled and on the ground. The restored lighthouse is starting to come alive as the scaffolding is being dismantled. We are so surprised at the amount of rust and scale on the steel only after 9 months on the island. The grade 12 galvanized structural bolts that connected it all together were seized with rust and had to be cut off using torches and grinders. Amazing how well the Sandstone had weathered after all of these years.

August 2021

A&E team is conducting Quality Control Inspections. “National Lighthouse Day” Lighthouse is illuminated for the Boat Parade.

Final Phases are being Completed. These were the add/alternates to the Contract that were incorporated into the scope of work.

Stamped Concrete Floor

Membrane Waterproofing – Athens Building Corp. is a certified HENRY Contractor. We are digging to the original foundation in order to ensure water tightness.

Hurricane Proof Glazing is completed

The Final Piece……..The new Pharos LED Light.

September 2021 – Project Completed

This was a one of a lifetime project for Athens Building Corp. First and foremost, we would like to thank David Mayhew, Superintendent for all that he endured and overcame to complete this project with the success that he did. Secondly, the all of the good people of Mathews County, Virginia for their hospitality and kindness. This project would not have been a success without all of the community support.

Final work that we are all proud of….

In The News… Front Page Headline Article in Richmond Times Dispatch